Introduction

In the global soft fruit industry, the spotlight often shines on genetics, yield, and export markets. Yet, one of the most overlooked — and most costly — issues is what happens just before and after harvest.

For berries like blueberries, strawberries, and raspberries, these critical windows determine not only how much fruit reaches the market, but how much quality and profit is lost along the way.

Recent studies reveal that improper pre- and post-harvest handling can lead to 20–50% fruit losses, depending on the berry type and region (Moggia et al., 2017; Zaro et al., 2014). In Southern and Eastern Europe, where cold chain infrastructure is inconsistent, these figures may climb even higher.

The fragile physiology of berries

Berries are among the most perishable fruits in horticulture. Their thin skins, high respiration rates, and sensitivity to bruising make them especially vulnerable during harvest and post-harvest handling. Small mistakes at this stage — harvesting too late, using deep crates, or delaying cooling — can result in rapid decay, softness, off-flavors, and total loss of marketable fruit.

Fig 1: Other diseases, such as Mucor and Rhizopus, can also develop during cold storage and transport.

For example, raspberries can lose up to 60% of shelf life if bruised or harvested overripe (Perkins-Veazie & Collins, 2002). Strawberries picked during hot mid-day hours are more susceptible to Botrytis, cold store decay, and dehydration (Zaro et al., 2014). Blueberries, if not pre-cooled quickly, will soften within days and lose their firmness and bloom — two critical quality attributes (Moggia et al., 2017).

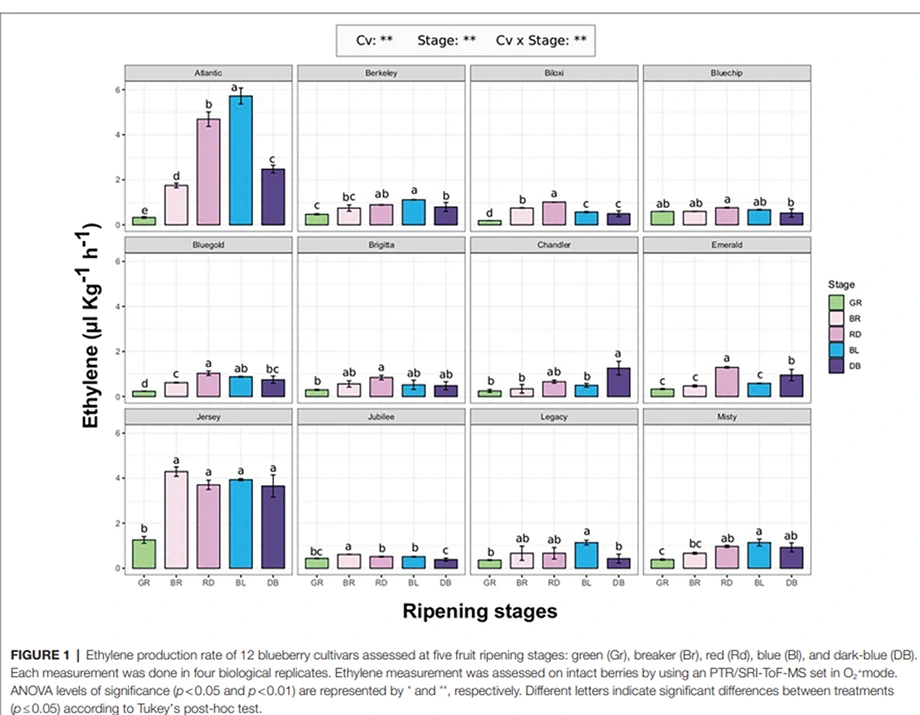

Fig 2: Ethylene production affects blueberry fruit texture and storability. Differences are visible between varieties and fruiting stages. Ethylene production rate of 12 blueberry cultivars was assessed at five ripening stages: green (Gr), breaker (Br), red (Rd), blue (Bl), and dark-blue (DB). Each measurement was done in four biological replicates.

Farneti et al. (2022) summarize that there is still debate over whether the blueberry is a climacteric fruit (i.e., one that depends on ethylene for ripening). Results vary widely due to differences between genotypes more than between species. Some cultivars show clear ethylene peaks during ripening and storage, while others do not, suggesting genotype-specific ethylene production behavior.

Common Pre-Harvest Errors

Late Harvest

Harvesting fruit beyond its optimal ripeness increases internal sugar and softness, making it more prone to microbial decay. In blueberries, late harvest has been linked to 30% shorter shelf life and increased fungal growth (Moggia et al., 2017).

Lack of Harvest Training

Workers unaware of correct maturity stages or handling protocols often damage fruit. Even slight pressure or dropping a crate can cause invisible bruises that result in rot 24–48 hours later.

Inadequate Field Sanitation

Infrequent removal of overripe or diseased fruit promotes fungal outbreaks, especially Botrytis cinerea, a major postharvest pathogen in strawberries and raspberries (Valero et al., 2007).

Shelf-life Loss: Effect of Field Temperature and Delayed Cooling

For example, keeping blueberries in the field after harvest — especially at high temperatures — significantly accelerates quality loss and reduces postharvest shelf life.

Table 1: Estimated losses in shelf life per hour as a function of ambient field temperature

| Field Temperature (°C) | Shelf Life Loss per Hour | Sources |

|---|---|---|

10 | 0.2 days | Beaudry, 1992 |

15 | 0.5 days | Prange & DeEll, 1997 |

20 | 0.8 days | Drake & Nelson, 1990 |

25 | 1.2 days | Drake & Nelson, 1990 |

30 | 1.8 days | Hardenburg et al., 1986 |

35 | 2.5 days | Hardenburg et al., 1986 |

It is recommended to cool down the fruit to below 10°C within 1 hour after harvest, especially when ambient temperatures exceed 25°C. These practices help preserve firmness, flavor, and reduce the development of fungal diseases like Botrytis

Post-Harvest Mistakes and Their Cost

No or Delayed Pre-Cooling

Every hour that berries remain at field temperature can cost up to one day of shelf life (Smilanick et al., 2006).

Poor Cold Chain Management

According to the EU Fresh Chain Project (2021), only 48% of berry producers in Southern Europe maintain a continuous cold chain from field to retailer. This leads to a 15–35% loss in marketable fruit.

Improper Packaging

Deep containers, lack of ventilation, and overfilling exacerbate bruising and overheating.

Lack of Cold Chain in Europe: A Hidden Fruit Killer

Even when harvest is executed well, many farms in Southern Europe still face major losses due to incomplete or broken cold chains. Key problems include: no pre-cooling units at farm level, warm delays during loading and transport, retailers not storing berries below 5°C, and poor humidity control.

Table 2: Situations happening on the berries chain

| Problem | Description | Countries most affected |

|---|---|---|

Delayed pre-cooling | Fruit left warm for >2h after harvest | Spain, Romania, Greece |

Inconsistent cold storage | Poor insulation, unreliable temperature control | Eastern Europe, Southern Etal |

Warm transport | No refrigerated trucks or variable temps in transit | Morocco to Europe routes, rural Portugal |

Retail storage | Berries held at >6°C in stores | Across Europe, especially small retailers |

Table 3: Losses on the major berry crops

| Crop | Losses without proper cold chain | Source |

|---|---|---|

Strawberries (Spain) | 20–35% quality loss due to delayed cooling and poor transport | Valero et al., 2007 |

Blueberries (Poland) | Up to 30% shelf life reduction if cold chain breaks post-harvest | Wojdyło et al., 2019 |

Mixed Berries (Portugal, Greece) | 25% reduction in marketable fruit if stored above 6°C | Dinis et al., 2022 |

Best practices: preventing losses from field to market

Harvest timing

Harvest blueberries in the early morning when ambient temperatures are lower, which helps minimize field heat and respiration rates. Avoiding harvest during the hottest part of the day, will help to improve impact, as elevated temperatures accelerate softening, water loss, and microbial growth.

Ripeness

Pick berries at the optimal commercial maturity stage—fully blue with no redbacks, ensuring the best balance between flavour and firmness. Overripe fruit is more prone to bruising, leaking, and postharvest decay during handling and transport.

Crate design

Use shallow, ventilated containers with smooth inner surfaces and soft handles to minimize mechanical injury. Proper crate design reduces pressure on the fruit at the bottom layers and improves air circulation during cooling and storage.

Pre-cooling

Initiate forced-air cooling immediately after harvest and aim to reduce fruit pulp temperature to 0–2°C (on long distance) within 30 to 60 minutes. On practice, this happens with 6 to 10◦C range due to proximity of market, while the upper comment, is implemented long distance procedure. Rapid pre-cooling is critical to slow down respiration, delay ripening, and prevent early decay, effectively extending shelf life by several days. This procedure will need that all infrastructure of packing must be under temperature-controlled environment on the same range of temperatura.

Cold chain management

Maintain a consistent cold chain of 0–4°C from the farm to the retail point. Any breaks in the cold chain can lead to condensation, accelerated microbial growth, and significant shelf-life reduction.

Retail storage

Keep berries at temperatures below 5°C at the retail level, ideally with 90–95% relative humidity. Controlled storage conditions preserve visual appeal, reduce shrivelling, and maintain textural and nutritional quality for consumers.

Conclusion

In 2021, EU Fresh Chain Project study across Spain, Greece and Romania found that only 48% of berry producers had access or use to cold chain systems, and less than 30% could guarantee cool temperatures during transport to retailers.

Factually, the journey from field to fork for berries is short in time for the European case but long in risk. Poor or inadequate practices in the final stages of the production cycle can silently undo an entire season’s investment. With tightening export standards demands from retail and growing consumer expectations, ensuring quality on the operation processes in pre-harvest and post-harvest handling is not a luxury — it's a necessity.

So with that said I leave you with a last final question: “Are we doing the best we can to reduce fruit waste in Europe?”

Jorge Duarte, Hortitool Consulting

References

- Moggia, C., Graell, J., Lara, I., & Schouten, R. (2017). *Differences in softening rate of blueberry fruit during storage are related to harvest time and genotype*. Postharvest Biology and Technology, 123, 1–8.

- Zaro, M. J., Keunchkarian, S., & Vicente, A. R. (2014). *Harvest time and heat affect strawberry quality*. Scientia Horticulturae, 179, 193–200.

- Pantelidis, G. E., et al. (2007). *Antioxidant capacity of strawberry, raspberry, and blackberry fruits during storage*. Food Chemistry, 102(3), 774–778.

- Perkins-Veazie, P., & Collins, J. K. (2002). *Shelf life and quality of fresh raspberries as influenced by postharvest handling*. Postharvest Biology and Technology, 25(2), 205–212.

- Hancock, J. F., et al. (2020). *Blueberries* (2nd ed.). CABI International.

- Dinis, L. T., et al. (2022). *Cold chain failures in berry fruit retail: consequences for firmness and consumer rejection*. European Journal of Horticultural Science, 87(2), 79–87.

- Valero, D., et al. (2007). *Effects of cold storage and packaging on quality of Spanish strawberries*. Postharvest Biology and Technology, 44(1), 48–57.

- Wojdyło, A., et al. (2019). *Drying and storage effects on quality of Polish highbush blueberries*. LWT - Food Science and Technology, 99, 594–602.

- EU Fresh Chain Project. (2021). *Evaluation of Cold Chain Performance for Perishable Fruits Across Southern Europe*. Horizon 2020 Report.

- Beaudry, R.M. (1992). *Effect of oxygen and carbon dioxide partial pressure on selected phenomena affecting fruit and vegetable quality*. Postharvest Biology and Technology, 1(3), 191–204.

- Prange, R.K., & DeEll, J.R. (1997). *Preharvest factors affecting postharvest quality of berry crops*. HortScience, 32(5), 824–830.

- Drake, S.R., & Nelson, J.W. (1990). *Influence of harvest and postharvest handling on quality of blueberries destined for fresh market*. Journal of Food Quality, 13(2), 133–141.

- Hardenburg, R.E., Watada, A.E., & Wang, C.Y. (1986). *The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks*. USDA Agriculture Handbook No. 66.

- Farneti, B., Khomenko, I., Ajelli, M., Emanuelli, F., Biasioli, F., & Giongo, L. (2022). *Ethylene Production Affects Blueberry Fruit Texture and Storability*. Frontiers in Plant Science, 13, 813863. https://doi.org/10.3389/fpls.2022.813863