The innovative device aimed at manual blueberry harvesting demonstrated a 9.7% increase in harvest productivity, a reduction in fruit losses by 87%, and accelerated worker harvest speed by an average of 50%.

The Catholic University of Temuco, UCT, has achieved a significant milestone in supporting agriculture with the development of an innovative tool for manual blueberry harvesting, which improves productivity and working conditions for sector workers.

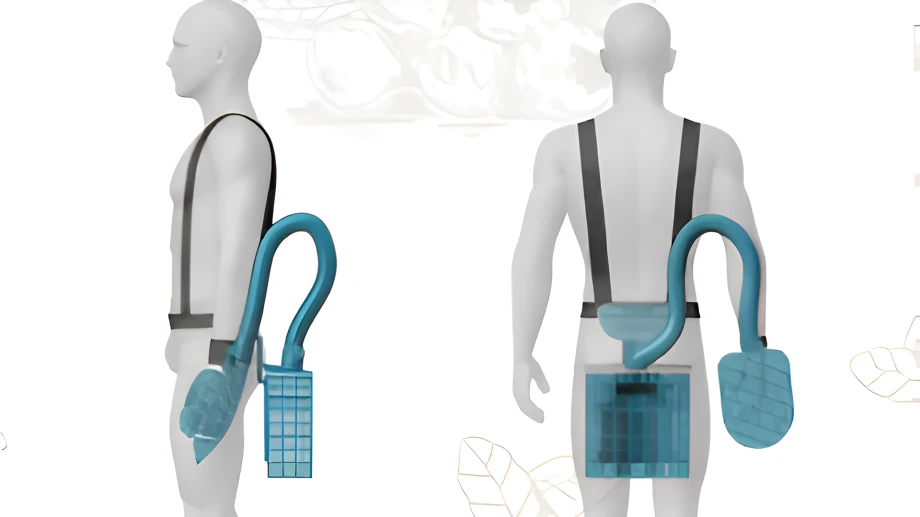

The harvesting tool, which utilized 3D printing technology in its initial prototype, was designed to adapt to various working conditions in Chile, considering both the worker’s anthropometry and ergonomic conditions and requirements that allow for the efficiency of the blueberry harvesting process. With an optimized design to reduce fatigue and physical stress, workers can now harvest blueberries more quickly and with less effort.

This development was made possible by a project from the National Research and Development Agency, ANID, titled “Design, validation, and commercialization of an essential tool for seasonal workers during manual blueberry harvesting, improving their productivity and working conditions,” awarded through the “XI Contest for Research Valorization at the University 2021” program.

Thanks to the inventors Javier Ignacio Dueñas Catalán (Designer graduated from the UCT School of Design) and Mg. María Paula Simian Fernández (academic at the UCT Faculty of Architecture, Art, and Design), and the crucial support of the Directorate of Innovation and Transfer (DIRITT) through the UCT Innovation and Transfer Coordination, the tool obtained a Registered Utility Model title that guarantees and protects its commercialization, and it will soon be available for productive use.

Increase in Harvest Productivity and Worker Well-Being

Field testing of the tool in various scenarios demonstrated a 9.7% increase in harvest productivity and also an increase in worker harvest speed by an average of 50%. Additionally, it reduced fruit losses during the manual harvesting process by 87%, representing a considerable advancement towards efficiency and sustainability in fruit harvesting, impacting the local economy.

This is possible thanks to its preventive design that addresses the critical processes associated with fruit loss and allows the worker to harvest continuously with a consistent capture.

On the other hand, it is important to highlight that seasonal workers using this ergonomically designed device experienced a significant reduction in muscle fatigue, preventing future musculoskeletal injuries and pain in areas such as the lumbar spine, cervical spine, and scapulohumeral joint, which are common in traditional harvesting.

“This innovative tool represents a great leap forward in terms of ergonomics, human factors, and design; improving the efficiency of manual blueberry harvesting. Carefully and specifically designed to improve both the harvesting process and the working conditions of the workers; the project made an effort to prioritize the health of the worker and the efficiency of the production system.

Thanks to this tool, we can ensure faster and less strenuous harvesting, significantly reducing fruit losses and work-related injuries among harvesters. We are committed to innovation that not only optimizes processes but also takes care of our people. This development is a step towards more sustainable and humane agriculture,” said Paula Simian, co-inventor of the tool.

“Our invention and its refinements not only increase field efficiency but also significantly improve workers’ quality of life. By reducing physical strain and the time required for harvesting, we are contributing to a safer and more productive work environment.

This achievement clearly reflects how science and technology can work together to solve real challenges in our society, making agriculture more sustainable and respectful of those who cultivate our land,” said Javier Dueñas Catalán, co-inventor.

For his part, the Director of DIRITT UCT, Rodrigo Aedo, stated: “This tool not only reflects our commitment to innovation and technology transfer but also to the well-being of our community. We are putting technology at the service of people and improving the working conditions of those who depend on agriculture for their livelihood.”

The Catholic University of Temuco, through DIRITT and in collaboration with design professionals and co-inventors Javier Dueñas and Paula Simian, plans to continue working on this project, seeking to explore new collaborations to perfect current conditions and integrate the tool into the market, rigorously meeting the needs of blueberry producers and harvesters both nationally and internationally.

Device Features

The device features an adjustable fastening system that adapts to the worker's body, minimizing physical effort and reducing the risk of injuries to the cervical and lumbar areas.

It includes a lightweight and durable container that stores blueberries without damaging them, preserving the fruit’s protective bloom.

Its modular design facilitates cleaning, maintenance, and adaptation to different sizes and varieties of blueberries.

Made from recycled polymers, the tool is durable even under high temperatures and ensures a long life in demanding field conditions.

Source: UCT