During the recent Berry Trend webinar, Thomas Drahorad presented some data from the Italian Berry Retail Monitor, which visits Italian large-scale retail points of sale weekly to analyze the assortment of the berry category in depth.

What aspects did you focus on in this analysis?

The Observatory analyzes over 20 parameters for each sample collected. In this case, we focused on two critical aspects that impact both the profitability of the points of sale and consumer satisfaction. We considered out-of-stock situations and product quality on the shelves.

Impact of Out-of-Stock Situations

What impact does an out-of-stock situation have?

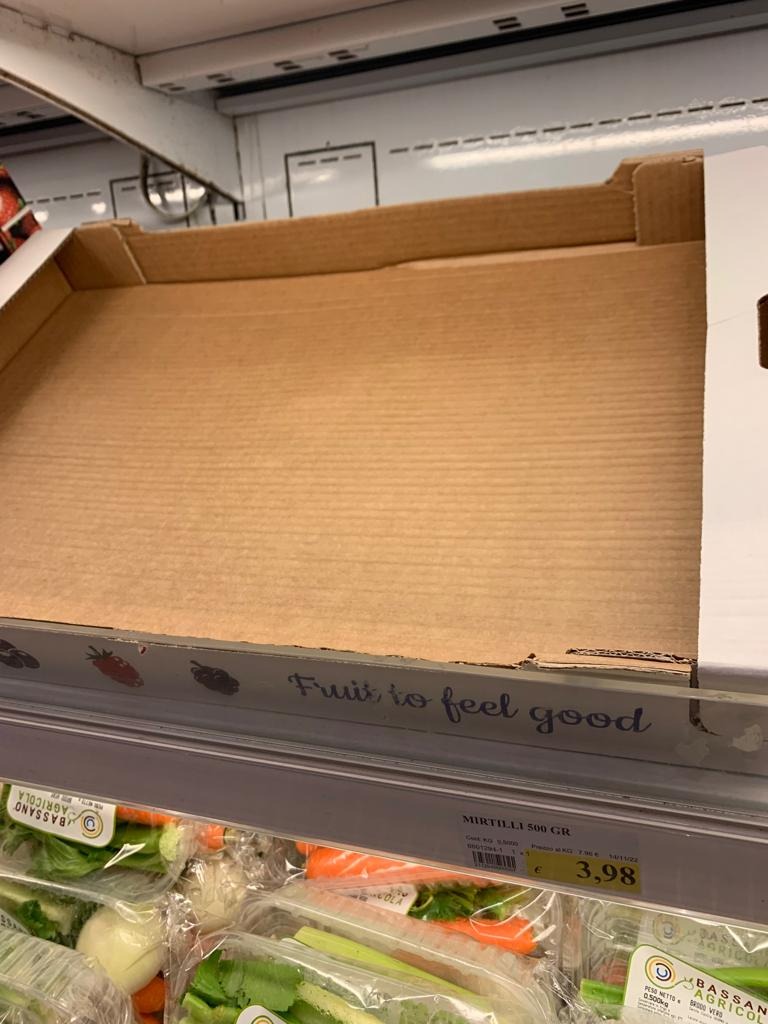

Out-of-stock situations occur when the consumer finds an empty shelf, meaning the label is there, but the product is not. This is different from a lack of assortment, which is a choice made by the point of sale. For example, some departments deliberately limit the assortment to one or two items, placing only blueberries and raspberries or just blueberries on the shelf. An out-of-stock situation, however, is an error; it is the tip of the iceberg indicating that the point of sale failed to complete the supply process successfully.

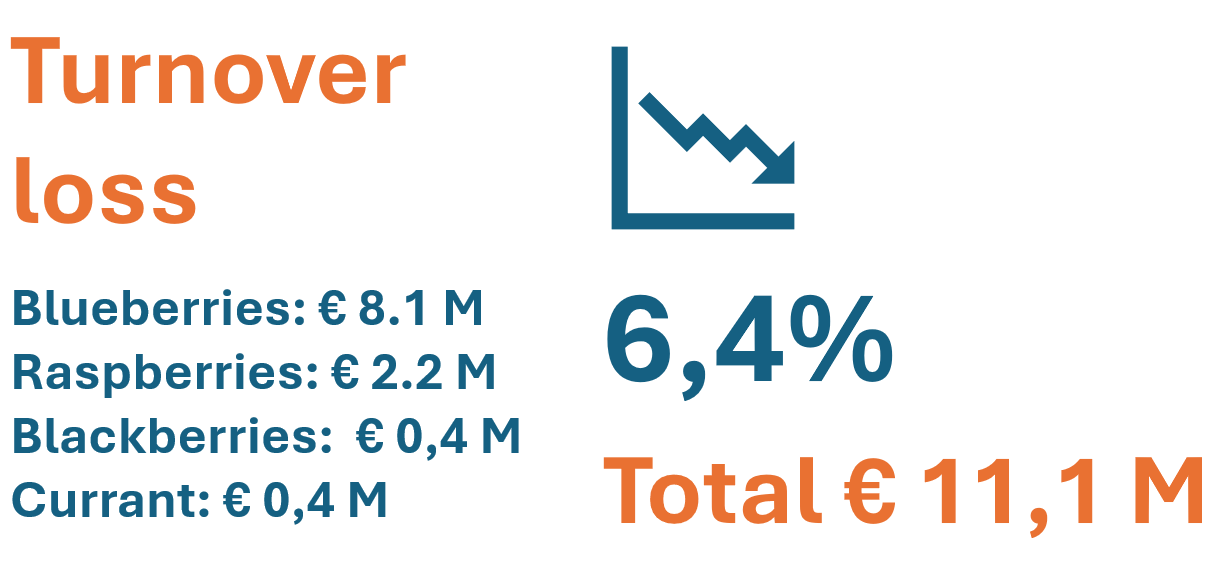

To give an initial sense of the severity of this phenomenon, we estimate that the impact of out-of-stock situations in the berry category in Italy exceeds 11 million Euros per year.

Main Causes

An impressive figure! Before analyzing the category in detail, what are the reasons behind this problem?

One of the most common causes is inaccurate demand forecasting. If actual sales far exceed expectations, stocks can run out quickly. Similarly, if demand is underestimated, the point of sale might not order enough products to meet consumer needs.

Also, delays or errors in the restocking process can lead to out-of-stock situations. This can occur due to inefficiencies in the order management system or inadequate communication between the point of sale and suppliers.

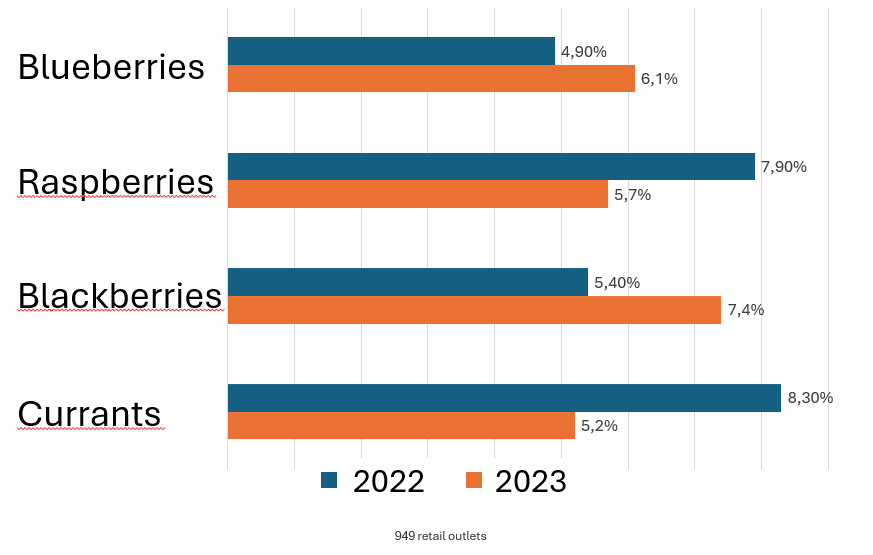

Out-of-stock in Italian retail outlets (source: Italian Berry)

Out-of-stock in Italian retail outlets (source: Italian Berry)

External Factors

Can there also be factors beyond the retailer's control?

Logistics play a crucial role in inventory management. Delivery problems, such as transportation delays, shipping errors, or customs issues, can prevent timely restocking of points of sale.

We must also consider unforeseen events, such as natural disasters, strikes, regulatory changes, or geopolitical situations, which can affect product availability and cause out-of-stock situations. These events can disrupt supply chains and make inventory management challenging.

These factors can act individually or in combination, increasing the complexity of inventory management: therefore, accurate and flexible planning is even more necessary for perishable products to minimize the risk of out-of-stock situations.

Impact on the Supply Chain

How widespread is stock depletion in berries with the consequent empty shelf?

For berries, the problem has a significant impact on the Italian large-scale retail sector. Between 2022 and 2023, we visited 949 points of sale and found out-of-stock situations around 5-6%.

Consequences

What are the consequences?

An out-of-stock situation can have several negative consequences for a retail company. Firstly, when products are not available, customers cannot purchase what they need. This can cause frustration and dissatisfaction, leading customers to turn to competitors who can immediately offer the desired products.

The lack of availability can reduce customer trust in the brand and its ability to meet their needs.

For berries, the impulse buying component, which occurs when the consumer, despite not having the product on their shopping list, buys it because they are attracted by what they see, is also lost. Obviously, if they do not see it, they will have no stimulus for an unplanned purchase.

Long-Term Effects

There are certainly also long-term effects that extend beyond the single missed purchase.

Indeed, the repeated unavailability of products can damage the reputation of the point of sale and the brand. Customers may perceive the company as unreliable or unprofessional.

Negative reputation can spread quickly through word of mouth or online reviews, negatively influencing the brand's image and reducing customer loyalty.

Economic Impact of Out-of-Stock Situations

How is the economic impact of out-of-stock situations estimated?

The most direct consequence of an out-of-stock situation is the loss of sales. Each missed sales opportunity represents a loss of revenue. Additionally, if customers turn to competitors for their purchases, the company not only loses immediate sales but also risks losing long-term customers.

For berries, out-of-stock situations represent an estimated loss of revenue of over 11 million Euros per year, with an impact of over 6% on the sector's revenue.

Economic impact of out-of-stock in Italian retail (2023, Italian Berry)

Economic impact of out-of-stock in Italian retail (2023, Italian Berry)

Preventing Out-of-Stock Situations

What are the remedies to avoid out-of-stock situations?

On one hand, there are general business management elements, and on the other, unpredictable or uncontrollable factors, which are more difficult to address.

But there are also other causes more specific to the category, such as lack of commercial planning and incorrect perception of the characteristics of individual products in the category.

Commercial Planning

Starting with commercial planning: how does it affect out-of-stock situations?

In 2022, the product with the highest out-of-stock rates was currants, which is essentially a product that can be stored for months, like apples. This means that the availability trend of this product can be predicted relatively easily: all it would take is coordination between supplier and retailer to ensure regular supply or to agree in advance on a temporary suspension of the product from the assortment.

Perception and Perishability

Regarding incorrect perception, what does it refer to?

I refer to both the category in general and the individual products. Regarding the category in general, a perception of high waste risk due to slow rotation and high perishability can also influence.

However, the waste risk has undoubtedly decreased thanks to the enormous growth in category sales (revenue has increased by +55% in the last three years), making it easier to manage.

Perishability Risk

The perishability risk remains, however.

The buyer's perception of perishability in itself does not determine this problem: in fact, we found that the products with the most out-of-stock situations in 2023 were blueberries (6.1%) and in 2022 currants (8.3%), which are the products that best preserve on the shelf in the category.

It would have been more understandable to have a higher out-of-stock rate for more perishable products like raspberries and blackberries, for which a more conservative purchasing policy could be more justified by the risk of waste.

On the other hand, the increasing prevalence of refrigerators in points of sale also helps mitigate this risk.

Conclusion

What can be concluded then?

A point of sale has all the technical and commercial tools to avoid out-of-stock situations, particularly with blueberries. Improving planning for this single product would be enough to recover over 8 million Euros in revenue, with a huge impact on the entire supply chain: economic results of operators would improve, consumer satisfaction and loyalty would increase, and the possibility of taking advantage of impulse purchases, which are undoubtedly relevant for the berry category, would grow.