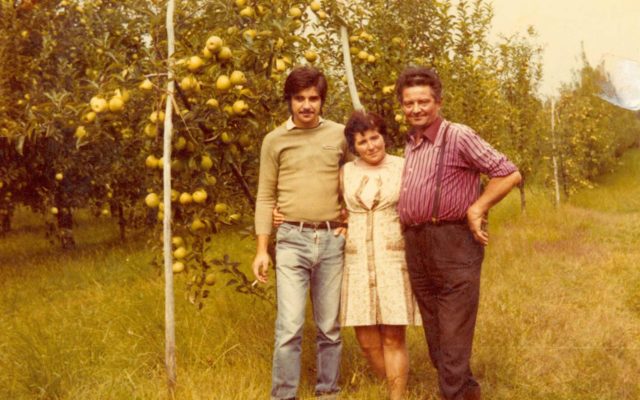

Cascina Blu was born in 2018 from the idea of Alberto Valentino and his need to make a drastic change of direction, returning to his origins and family traditions. After graduating in architecture from Turin Polytechnic, he realised that the call of the land was too strong, devoting himself full-time to the cultivation of blueberries in Ciriè, in the lower Canavese area.

THE HISTORY OF CASCINA BLU

With the help of his father, now retired, and the support of his entire family, he runs what is now a small family business committed to producing good, sustainable blueberries with an eye on research and innovation.

Why the jump from architecture to agriculture?

Quality of life. This, along with many other facets, was the main reason for my change of direction. I felt that my profession was becoming too cumbersome between me and my family, which, at the time of the first reflections on the change of direction, had recently grown with the arrival of Filippo. And then because, clearly, in my DNA, the land has a very important value; so I tried to understand if there was a possibility of leading a life at a slower pace, and I found it at blueberries . So my life has gone from working to give people quality in living to trying to give them quality in eating.

Where did the idea of growing blueberries come from in an area such as Chiria?

The area where we are located is mainly dedicated to dairy farming, and there are no orchards, but not so much for technical reasons as for tradition. We found here, just behind our house, the ideal conditions for growing blueberries and decided to take a risk by doing something that had never been seen here before; and then because it is here, at the foot of the Lanzo valleys, that our history has its roots and the emotional component has had its weight.

What are Cascina Blu's values?

Those of the rural tradition: transparency and authenticity. These are the basic values for us and for this reason we only produce one product, doing the impossible to make it genuine and natural. In the same way we like to show it to people without veils and thanks to our fields, which are crossed by a road, everyone can see and follow the agricultural activity step by step. These values go hand in hand with research, innovation and technology, which are our goal. We combine transparency with technology, and thanks to social networks we tell our followers what is happening in the fields on a daily basis, showing them everything that revolves around blueberries. With research, on the other hand, we seek technical solutions for managing the orchard to avoid the use of chemicals, to reduce consumption and emissions into the atmosphere and to obtain an increasingly natural product.

What are your main objectives?

Innovation is probably our most important goal, not only for running the plant but also for everything that goes with it. As of this year, following extensive research, we will be packaging our products in containers made from 100% recycled and recyclable paper. Reducing the ecological footprint of our product is fundamental for us and we are also working to be able, in the near future, to tell what is inside each individual package and to inform consumers about the real environmental "weight" of what they are eating by analysing the data collected throughout the production phase and thanks to a complete product traceability system. This is because we believe in local consumption of agricultural produce.

How was the 2020 season?

The year 2020 was our first real season. Our plants bore their first fruits and after a lot of hard work it was literally a party on the first harvest day. We were very satisfied with both the quality of the product and the quantity. We made a few mistakes, but they helped us to get through the next season, which is just around the corner.

Regarding the 2021 season, what are the prospects?

We feared disastrous consequences from the frost at the beginning of April when the buds were already swollen, but fortunately the temperatures in our orchards did not drop much and we did not record any significant damage. We expect a much higher production than last year and hope to be able to satisfy all our customers with a high quality product.

What is your production window? What varieties do you have in production?

Last year we made our first cut on 10 June with Duke and stopped at the end of July with the production of Aurora. In between we harvest from Ozark Blue and Draper. Within our two hectares of orchard planted with about 6,500 trees, we have a few hundred plants for experimentation where we test new varieties to evaluate their characteristics and to identify varieties that deserve to be planted in our area.

How did the need to invest in research come about?

We decided to use part of the plant for experimentation because we noticed some discrepancies between the bibliography and our reality (not very far from the large production centres of berries in the Saluzzo and Cuneo areas in general, but with different climatic and microclimatic conditions). This year's production window will be more or less the same, but with the lower seasonal averages, we expect there will be a few days' delay compared to last year; however, we are confident that we will be able to extend the production window at least until the beginning of August, thanks also to the anti-hail system installed this spring.

What steps do your blueberries take from the plant to the tray?

Very few in fact. Our aim is to offer the freshest possible product, which is why we try to reduce the number of processing steps at blueberry to a minimum. First of all, they are harvested by hand, one by one, after an initial careful selection on the plant. Once harvested, they are taken from the field to the laboratory where they are registered and hand-selected again. The smaller ones are used for processing, while the damaged, spoilt or unripe ones are discarded and used as animal feed. The first choice is weighed, placed in trays, labelled and immediately put on sale.

So does Cascina Blu also transform its blueberries?

Absolutely, we use the unsold part of the day or the second choice of product for the production of juices and compotes, which we have processed by an artisan workshop under our own brand name. The juices and preserves are made from fresh fruit of the highest quality only. We immediately chose not to process fruit that is commonly classified as "processed" in order to make products from top quality fruit and thus guarantee the customer an equally good, genuine and tasty product even if processed. And to satisfy all tastes we also have the line without added sugar that contains only and exclusively blueberries.

Has Cascina Blu obtained any certifications?

Not yet. Although we started with the organic certification procedure right from the start, Cascina Blu is currently in organic conversion and will be certified from the 2021 season. However, we are also working in parallel to obtain other certifications and awards.

How is your sales activity organised?

We have a sales point right in the middle of the fields and we work with local traders who sell our product in the squares of the most important towns in the area and we are working to establish commercial agreements with specialised shops.

In conclusion Cascina Blu is...

Cascina Blu was a big bet and still is. As I have already said, we are a small, mostly new company that will take some time to find its size and its place. We have made this choice in order to live at a different speed and we are succeeding. We have more quality time to devote to the family, which, moreover, grew a little more last year, and we have managed to produce some excellent blueberries to the approval and appreciation of our customers. We can only be satisfied and we are looking forward to the next challenge and working on the next of many innovations.