Production costs for highbush blueberries in Michigan exceeded $10,000 per acre in 2024 (about €23,250 per hectare), with expenses nearly matching revenues for an average blueberry field in the state.

This means that the average grower in Michigan operates at an economic breakeven point.

The budget included approximately $240 per acre (about €562 per hectare) for management, considered a labor cost: this represents an income for growers who directly manage their own fields.

Annual costs and harvesting

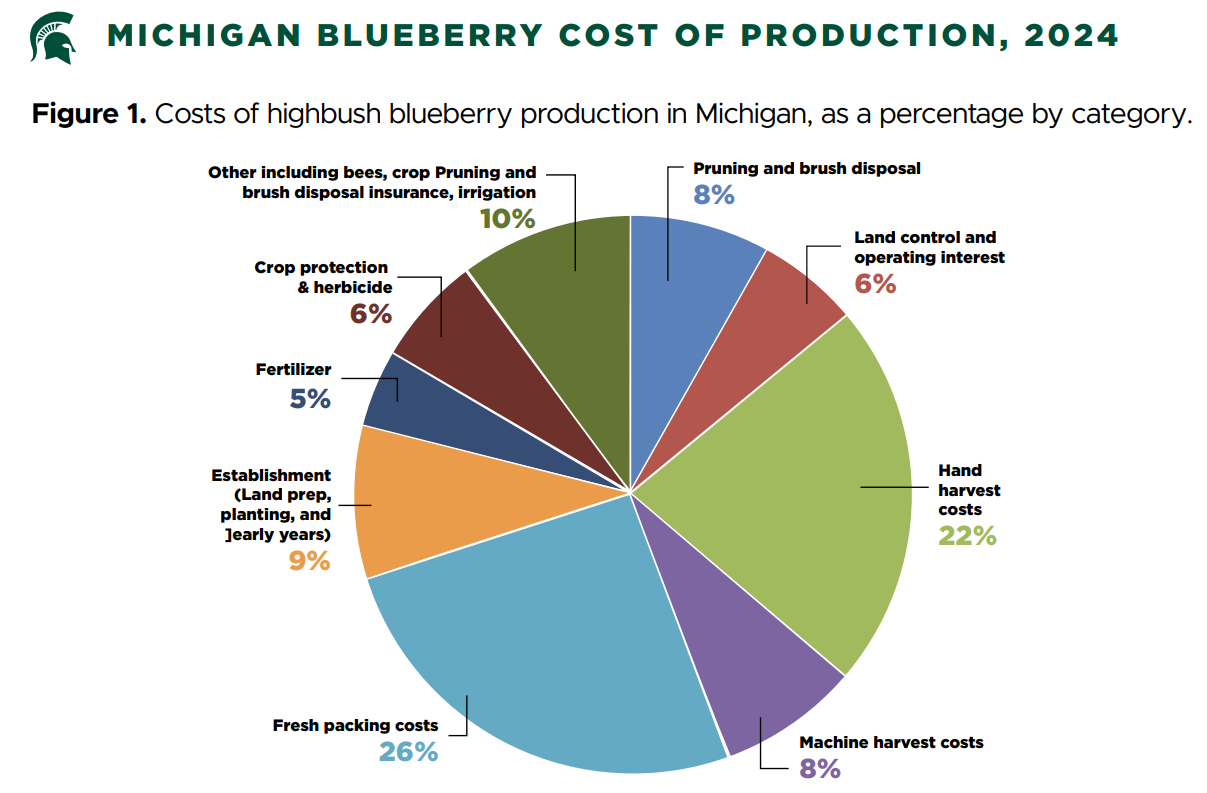

Annual costs for growing blueberries — including pruning, fertilization, and crop protection — make up about 29% of total costs.

Harvest-related costs, such as hand-picking and packing for the fresh market, account for almost 56% of the total.

The remaining 15% goes to operating interest, soil control costs, and establishment expenses.

Field establishment costs, including planting and non-productive years, are estimated at $23,956 per acre (about €55,750 per hectare).

Fixed and variable costs

Fixed costs related to machinery and equipment, land, and general packinghouse expenses account for at least 12% of total costs.

However, most production costs are variable and thus susceptible to input cost fluctuations.

For example, skilled and manual labor costs — rising due to higher wages — account for about 42% of total production costs.

Fresh market and strategies

The blueberry sector is increasingly focusing on fresh market production, with growers choosing cultivars and cultural techniques suited for this segment.

The use of harvest machinery for fresh-market blueberries is growing, involving up to 20% of harvested volume.

While up to 75% of blueberries may be intended for the fresh market, weather conditions and packing line rejects divert a significant portion toward processing or freezing, depending on the season.

As a result, the current sector split is approximately 54% for fresh market and 46% for processing.

High input and improved techniques

Many producers are adopting high-input strategies to increase profitability.

These strategies often include the use of improved cultivars offering quality benefits, along with more mulching at planting, foliar fertilization, drip irrigation, and other yield-boosting methods.

Most costs are tied to harvest and packing, including dedicated infrastructure.

Blueberries are among the top three fruits in Michigan by area or production volume, with 87 million pounds harvested on 16,900 acres in 2023, of which 54% were for the fresh market. In 2024, highbush blueberry production costs in Michigan exceeded $10,000 per acre, nearly matching revenues for the average blueberry field in the state.

Main Cost Drivers

More specifically, here’s a breakdown of the key cost drivers and management strategies in blueberry production:

Main Cost Drivers

Blueberry production costs are largely variable and sensitive to input shocks.

Total Annual Input Costs: About 29% of total costs, including pruning, fertilization, and crop protection.

Harvest Costs: The largest component, nearly 56% of total production costs, including manual and mechanical harvest and fresh packing. Manual harvest alone makes up over half of labor costs.

Labor: Around 42% of total costs during full production is attributed to manual (e.g., pruning, planting, harvesting) and skilled labor (e.g., tractor, truck operation). Labor costs have risen with wage increases. Average 2024 rates were $33/hour for skilled workers and $26/hour for other labor, including FICA and benefits.

Field Establishment Costs: Including non-productive years, estimated at $23,956 per acre (approx. €59,170/ha). Including partial production years (Years 4-7), total establishment cost is $27,504/acre (~€67,200/ha), amortized at $917 annually over 30 years (~€2,265/ha/year). These include:

Land Preparation: ~$8,447 (~€20,860/ha), including root/rock removal, soil analysis, disking, mulching, irrigation (solid-set frost protection, drip, pumps), and drainage systems.

Planting: Cost of bushes (~$5 each, ~€12.35/plant in pots, 1,452 plants/acre), labor, grass seeding, fertilization, soil control, property taxes, management, and interest.

Non-Productive Years (1–3): ~$1,951 per acre/year (~€4,820/ha/year) for soil aeration, irrigation, pruning/training, brush shredding, weeding, fertilization, mowing, crop protection, herbicides, porta-toilets, soil control, property taxes, management, and interest.

Fixed Costs: Machinery and equipment, land, and packinghouse overheads, accounting for at least 12% of total costs.

Other Operating Costs:

Pruning: ~$0.54 per bush (~€1.33/plant) or $784 per acre (~€1,935/ha).

Fertilizers: ~$436 per acre/year (~€1,080/ha): dry ($190), liquid/fertigation ($150), foliar ($96).

Crop Protection: Varies by cultivar, average $328.40 per acre (~€810/ha), higher for mid/late-season types.

Bees: 3.5 hives/acre at $68 per hive ($238/acre, ~€590/ha).

Food Safety: $60/acre (~€150/ha).

Crop Insurance: $85/acre (~€210/ha).

Management Cost: Included as labor cost, $240/acre (~€590/ha), income for self-managed growers.

Management Strategies

To improve profitability and respond to narrowing margins, many growers adopt the following strategies:

High-Input, Fresh-Oriented Strategy: A main strategy to boost profits.

Improved Cultivars: Offer better quality and higher yields.

Growing Techniques: More mulching, foliar feeding, drip irrigation, and yield-boosting practices.

Higher Yields: From 5,500 lbs/acre average to 7,500 lbs/acre with high input.

Higher Initial Costs: Double pruning/fertilizer costs, $7.50 per bush (~€18.50/plant), 120-yard mulch, 5 hives/acre for pollination.

Mechanical Fresh Harvest: Up to 20% of harvest. New cultivars adapt better, reducing labor costs.

Vertical Integration: Enables own packing, better agility, and valorization of culls.

Profit Impact: Despite higher costs, strategy yields $2,952/acre (~€7,285/ha) vs. $26/acre (~€64/ha) average. Break-even year 6 vs. year 7; establishment cost recouped in 14 years (vs. 37).

Replacing Old Fields: Due to yield decline and pests (e.g., blueberry stem gall wasp). New cultivars solve pest issues and save control costs.

Cost Reduction Strategies: Cost-saving strategies can boost income.

Low Land Costs: Owned or cheap farmland increases margins.

Direct Marketing: Selling directly can yield higher revenue.

Economies of Scale: Expanding operations reduces per-pound costs and increases returns.

Read and download the full study

Photo: Michigan Farm Bureau