Flexibility was perhaps the word most often repeated by Sergio Panini, the new agent for Italy of Earis & Berrypro, a Spanish company that produces machinery and technology for processing berries and fruit.

"We are 100 per cent manufacturers," said Panini, so we design, develop and implement every piece of equipment, but we don't stop there. Once the equipment is up and running, we take care of maintenance and troubleshooting, and if a part has to be replaced, because we are the manufacturer, we are also the direct supplier.

"In addition to the mechanical part, we also take care of the software for each piece of equipment, so that "wehave total control", which allows us to adapt each one to the specific needs of each customer; this is not a market exclusive to large manufacturers, but there are also small and medium-sized ones, each with their own requirements".

A TREATMENT OF ATTENTION FOR THE BLUEBERRY

This market has evolved a great deal in recent years and everything suggests that it will continue to do so in the future. From being virtually unknown, blueberry has become one of the most consumed products, which has brought with it the emergence of new quality standards in aspects such as flavour, crispness, firmness and, of course, taste. "Consumers know what they are buying and what quality they want," explained Panini and added that, precisely because of this, "we have developed equipment that takes the utmost care of the fruit".

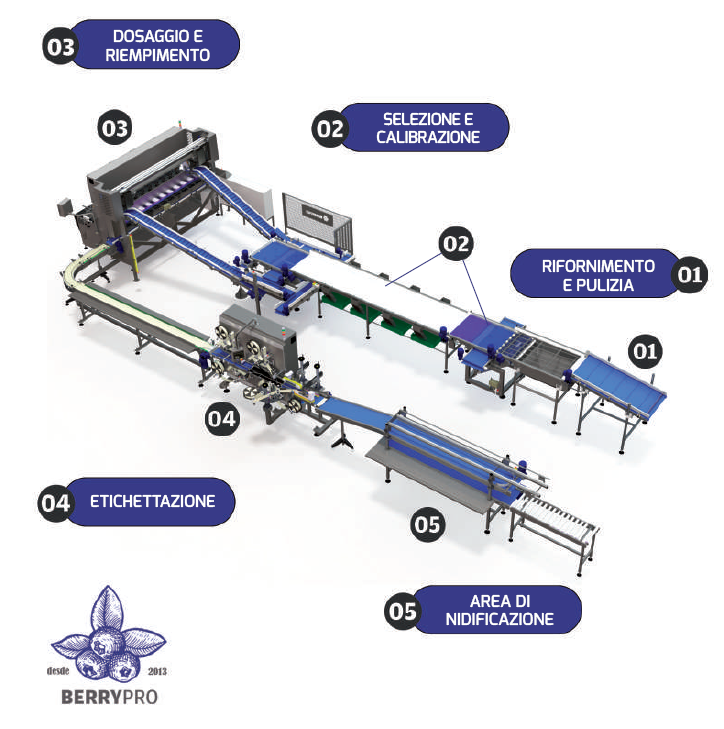

Thus, if there is one thing that characterises all its packaging solutions (Gaby, Híbrida Pro, EL12C...) it is its careful handling of blueberry: "We develop machines that minimise the impact on the fruit, as internal damage is not visible, but is detrimental to the shelf life of blueberry".

For Panini there is no doubt: "This is a job for the whole chain". And so, in order for growers to optimise their costs, reduce waste and ultimately offer their customers a product on which they have worked for months on quality, they need equipment that pampers the blueberry.

And all this without forgetting the importance of automating processes to reduce costs and thus be more competitive in a market with more and better players.

THE WORLD OF LABELLING

As consumer demands and quality requirements have evolved, so has labelling. The models and materials used have multiplied in recent years and, while years ago care for this image was in the background, it is no longer so: "Correct labelling sells," said Panini.

Precisely for this reason, and without forgetting the flexibility that characterises them, Berrypro has developed a labelling solution that "allows us multiple configurations, adapting to different labels and packaging, so that the customer has total freedom".

Three years ago, Berrypro decided to offer labelling solutions and not just a simple labellerto help its customers eliminate problems in this process. "There are incidents that cause real bottlenecks at the end of lines, up to and including complete and utter shutdowns," with the economic losses this entails. "Putting an end to technical stoppages is crucial," insisted Panini, who emphasised its continued commitment to R&D to "improve all processes".

Berrypro has developed labelling solutions such as the ET2SI, dual-head labelling machines that avoid production line stoppages due to lack of labels, as the second head starts automatically when the first has run out of labels. This reduces bottlenecks, unnecessary stops and the stress of changing rollers on labelling machines.

STRENGTHS

- Flexibility, and adaptability to any customer requirement.

- Good fruittreatment, maintaining 100% of the quality of blueberry.

- Labelling solutions that avoid production line stoppages.

- Cost savings due to high level of automation.

SPONSORED CONTENT